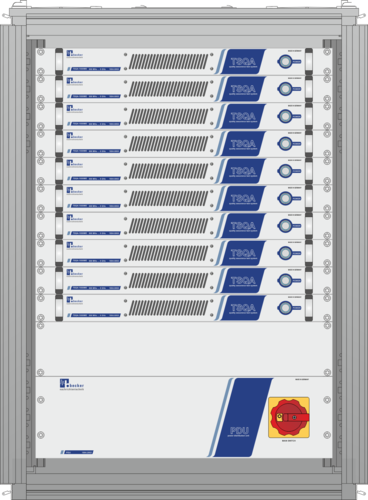

TSQA-80XME

Compact, full automatic HTOL RF test system for 80 devices under test (DUTs) with up to 500 mW per channel and a bandwidth from 300 MHz up to 6000 MHz. The frequency range covers all cellular, C2X and connectivity systems, including modern 5G components. The system offers high level accuracies which be achieved with automatic level control (ALC) loops in each output. The system has an internal CW signal source with an optional pulse modulator and a graphic user interface (GUI) for an intuitive handling.

300 ... 6000 MHz 19", 15 U up to 0.5 W RF power Automatic Level Control (ALC)

For an automatic monitoring of the transmission parameters (gain of insertion loss) of the DUTs the system offers 80 channels with high dynamic level detectors with high power capability. TSQA-80XME is housed in a 19“ system rack with 15 U. Depending on the position of the temperature cabinets at the customer site, there are variants with RF ports on the right or left site. The position of the RF ports allows to minimize cable length and the associated power loss.

High Isolations

To avoid mutual influences of the DUTs during the tests, TSQA-80XME has high isolation properties between the channels.

System Control

The HTOL system offer a LAN interface with a graphic user interface (GUI). Via remote interface test parameters like output power, cable type and length can be entered. The software automatically calculates the losses of the cables and presents power levels always with respect to the cable head.

Automatic Test Sequencing

With help of the option “Automatic Test Sequencing” TSQA-80XME carries out HTOL tests autonomously. The user defines test parameters like test duration, warm-up time and limits for insertion losses of the DUTs before starting the test. After the predefined test time the system removes the RF power from all DUTs. During test the system monitors DUT health continuously. The RF power can be taken off individually and automatically from DUTs after failure. This allows the best root cause analysis of the failure.

Latest modification: 31.03.2022